For a customer in the glass-making industry who successfully manufactures bioreactors out of glass tubes for the production of biomass through photosynthesis, new solutions were needed. The constantly increasing size of the plants also requires the possibility of a rapid modular expansion in addition to a cost-effective assembly and disassembly for cleaning the glass tubes. In this regard, the pipe joint made from a rubber-plastic composite developed by Jäger has proven its worth.

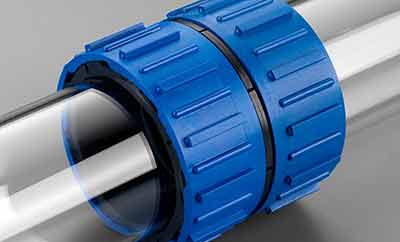

In the automotive industry and in the field of waste water aeration, the rubber-plastic composites directly developed by Jäger have proven their worth a million times over. To form a rubber-plastic composite a process is used where a freshly molded plastic component is sprayed with rubber without an additional primer. As a pioneer in this field Jäger has developed a wide variety of material pairings out of elastomers and thermoplastics with their own in-house elastomer chemicals, which are manufactured in their own mixing plant. The pipe connector produced by this process are ergonomically, economically and ingeniously simple.

The challenges: Bioreactors made of glass tubes

For a customer in the glass-making industry who successfully manufactures bioreactors out of glass tubes for the production of biomass through photosynthesis, new solutions were needed. The constantly increasing size of the plants, whose products are used in the renewable energy industry, in cosmetics and in the food and feed production, requires the possibility of a rapid modular expansion in addition to a cost-effective assembly and disassembly for cleaning the glass tubes.

Previously, glass pipes, pipe bends and valves were joined together with sleeves, which were connected with shrink tubing that had been shrunk. The maximum system pressure was 1.5 bar. This connecting system was destroyed for cleaning or with expansion of the glass tube pieces to be subsequently replaced by a new

piece.

This was now a challenge for Jäger, because the client’s order was to develop a connecting and closure system that:

This was now a challenge for Jäger, because the client’s order was to develop a connecting and closure system that:

• is pressure-tight to 6 bar,

• has no influence on the flow inside the tubes,

• fulfilled nearly all requirements for media resistance (depending on requirements),

• can be made electrically conductive,

• is ergonomically fatigue free with high reliability and can even be mounted and dismantled by unskilled labor,

• can be reused,

• is easy to assemble without electric power tools,

• has a 10 year warranty,

• and has a marketable price.

The result: A Universal Plastic Rubber Quick Release Connector

The newly developed quick connector from Jäger has significant advantages over the previously used connection system. In particular, reusability, significantly easy installation as well as the significantly reduced glass breakage due to too high torque when tightening the hose clamps are significant features. Another factor is the significantly higher working pressure of the system when using the Jäger connector which allows for faster and more efficient cleaning of the equipment.

In the three years since the new pipe connector has been in use, the requirements have been continuously specified in close cooperation with the customer and amended to the effect that the significant benefits are preserved, and the price could be reduced by about 40%. This is a further example how Jäger, through cooperative development and aftermarket launch, can continue to improve a product to the benefit of all stakeholders.